Why any warehouse needs a stretch wrapping machine today

Why any warehouse needs a stretch wrapping machine today

Blog Article

Discover the Perks of Making Use Of a stretch wrapping machine for Reliable Packaging Solutions

In the world of product packaging options, performance is key. Automation has actually produced significant developments, such as the stretch wrapping machine. With its capacity to wrap items securely and rapidly utilizing elastic plastic movie, it supplies a high level of accuracy and rate. It's not almost wrapping products, yet additionally regarding reducing labor prices, minimizing waste, and maintaining aesthetic allure. What makes these makers a game-changer in the product packaging market?

Understanding the Functionality of Stretch Wrapping Machines

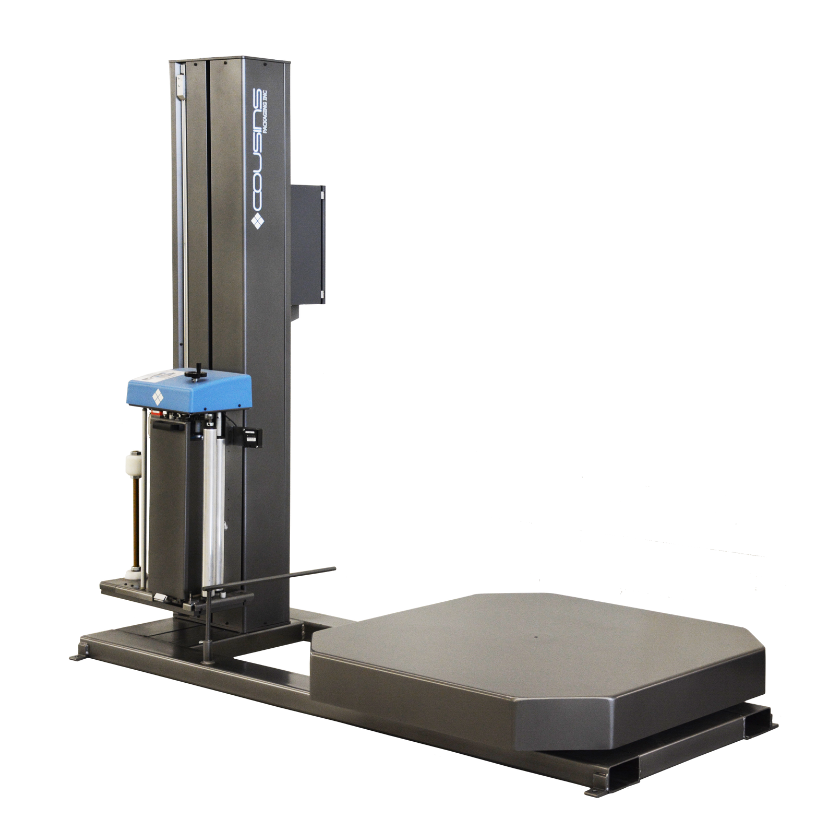

Originating the product packaging industry, stretch covering makers enhance the process of safely packaging products for transportation or storage space. These advanced devices utilize an easy yet efficient mechanism, using an elastic plastic film that is twisted around items, offering security and protection. The products, typically organized on a pallet, are revolved as the film is dispensed, guaranteeing a limited and safe cover.

The movie's flexibility serves a dual purpose: it firmly binds the products together, lowering the danger of damage because of movement, and it provides a barrier against dust, dampness, and other possible harmful aspects. Additionally, the clear nature of the stretch movie enables very easy recognition of the packaged products.

The equipments vary in their procedure mode, with some being semi-automatic, calling for marginal human intervention, and others being totally automated, efficient in independently managing the whole covering procedure. Despite their setting, stretch covering equipments are a foundation of effective and safe product packaging.

Just How Stretch Covering Machines Enhance Productivity

Enhancing performance levels dramatically, stretch covering equipments simplify the product packaging procedure with their automated capabilities. These innovative equipments enable business to wrap a high quantity of bundles swiftly and efficiently, delivering a regular covering result that hand-operated methods just can not match. This speed and consistency equate straight right into raised productivity, allowing organizations to fulfill requiring supply routines and client assumptions.

In addition, stretch wrapping devices need marginal human treatment. Once the device is established and the covering parameters are configured, the equipment can operate individually, maximizing staff members to focus on other important tasks. This automation not only lowers labor prices however likewise eliminates human mistakes, guaranteeing the high quality of covering remains consistent.

Furthermore, using stretch covering equipments typically brings about less downtime. stretch wrapping machine. With their robust style and reliable procedure, these machines are less vulnerable to break downs and upkeep concerns, guaranteeing undisturbed process and boosted performance

Decreasing Product Waste With Stretch Wrapping Machines

While read enhancing efficiency, stretch wrapping makers additionally play an important function in minimizing product waste. The accuracy of these machines ensures that each package is covered with the exact quantity of material required, reducing excess waste. This precision not just leads to a cosmetically pleasing and constant bundle, yet also contributes considerably to ecological sustainability.

Fundamentally, the use of stretch covering machines in a packaging line is not only a step in the direction of reliable productivity, but also a jump in the direction of environmentally friendly methods by considerably reducing material waste.

Cost Reduction: A Secret Advantage of Stretch Covering Machines

Along with mitigating material waste, one more substantial advantage of stretch wrapping machines is their potential for cost decrease. These machines are efficient, requiring less hand-operated labor for packaging products, thereby reducing down on labor costs.

Moreover, stretch wrapping machines utilize much less material to package products securely as contrasted to traditional covering techniques. This effective use materials not just minimizes waste yet also decreases expenditure on product packaging products.

The devices likewise decrease damages to products throughout transport. With durable and secure packaging, the threat of product damages reductions, minimizing the costs related to item returns and substitutes.

Ultimately, the rate and effectiveness of stretch wrapping devices can enhance production prices. Faster product packaging times mean that businesses can package and ship more products in less time, improving overall performance.

Carrying Out Stretch Wrapping Machines in Your Packaging Refine

Offered the excellent advantages of stretch wrapping machines, integrating them into your packaging procedure can be a game-changing decision. The execution process needs mindful preparation and training to make sure optimum usage. An analysis of the existing packaging procedure is essential to identify the ideal machine kind and dimension (stretch wrapping machine). The choice must align with the plan go to these guys dimensions, weight, and the quantity of products to be wrapped daily.

Training team on machine procedure is vital. This consists of recognizing the equipment's capabilities, troubleshooting typical problems, and adhering to safety and security guidelines. By doing so, businesses can make certain a reliable, cost-efficient product packaging process, reaping the full advantages of their financial investment in stretch wrapping devices.

Verdict

In conclusion, stretch covering makers supply reliable, affordable product packaging remedies. These equipments ensure item security and defense, while also delivering visually pleasing packages.

As soon as the device is set up and the wrapping parameters are configured, the machine can operate independently, releasing up workers to focus on other vital tasks.While enhancing productivity, stretch covering makers likewise play a vital role in reducing product waste.Provided the remarkable advantages of stretch wrapping equipments, including them right into your packaging process can be a game-changing choice - stretch wrapping machine. By doing so, organizations can make certain an effective, cost-effective product packaging process, gaining the complete benefits of their financial investment in stretch wrapping makers

In conclusion, stretch covering devices supply effective, cost-effective product packaging solutions.

Report this page